Stormwater Market Applications

A stormwater discharge is defined by the US Environment Protection Agency (EPA) as rainwater or snowmelt runoff. These fresh waters become polluted as they flow over modern manmade structures like roads, parking lots, industrial sites, roofs, suburban lawns, farm land, etc. An abundance of suspended pollutants can easily ride piggyback on sediment particles in such water flows. These polluted waters are a known contributor to poor water quality levels in receiving streams that suffer fish kills, and other environmentally harmful side effects.

To better control non-point source stormwater runoff pollution, the EPA has extended its rules to cover any parcel of disturbed land of three acres or more. The initial runoff of stormwater contains highly concentrated road salts, calcium chloride, motor oil, fuel and other corrosive chemicals that effect storm sewer pipes according to the water’s acidity or alkalinity. Crumpler’s inert HDPE corrugated plastic pipes will not react with this potent “first-flush” stormwater. The chemical resistance of CPP’s Single Wall and Dual Wall Smooth Core/n-10 pipes makes them ideal for the use in Saltwater environments and other stormwater systems as they not only eliminate internal pipe wall corrosion, but also eliminate the exterior pipe wall corrosion caused by corrosive soils. The need to remove untreated, corrosive natural soils from the pipe trench site, and import non-corrosive offsite backfill is eliminated.

Labor is the largest cost component in any buried pipe system.Extra labor caused by the removal of corrosive trench site soil can make contract bid work in these areas a non-option. CPP pipes also meet the corrosion needs in snow-belt areas that must endure much winter road and parking lot salt-melt runoff.

For Stormwater runoff drainage control and Stormwater treatment polishing systems, CPP’s inert HDPE raw material based pipes offer both Corrosion Resistances as well as H-20 (32,000 lbs/axle) Traffic Live Loadbearing capability.

CPP traffic load culvert pipes have been used on Industrial Roads, Airports, Private Development Communities and Farm Roads for since 1985. From 1989 forward a number of state DOT’s have approved it for driveway culvert and catch basin/slope-median drains. State DOT HDPE pipes have been shown to give satisfactory service when installed at depths as Shallow As Twelve Inches (12″) and As Deep As One Hundred And Four Feet (104′) in H-20 traffic bearing live load situations.

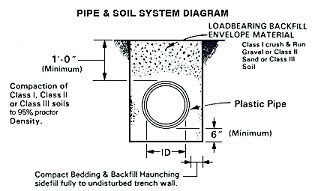

This wide range of depths is facilitated by burying the pipe in a Good Quality Soil Bearing Envelope that eliminates soft voids around the pipe so the pipe will not be prone to shift when traffic loads are applied. When traffic is applied, the flexible corrugated plastic design can utilize the stable compacted sidewall backfill for loadbearing support.

Both CPP Dual Wall Smooth Core and CPP Single Wall corrugated meet the same AASHTO plastic pipe standards that cover corrugated HDPE plastic pipes. The two styles are differentiated by the addition of the letter “S” or the letter “C” to the end of the appropriate AASHTO pipe size spec. The “S” indicates a smooth interior wall, and the “C” indicates a corrugated interior wall. AASHTO-M-242 cover sizes 3″ to 10″, and AASHTO-M-294 covers 12″ to 48″. The AASHTO standards are based on the ASTM-F-405 (3″ – 6″) and ASTM-F-667 (8″ – 24″) single-wall corrugated HDPE pipe specs.

To meet AASHTO live load H-20 culvert burial standards, CPP pipes should be buried in a loadbearing envelope of Class I, Class II or Class III compacted soil. If a Class I stone of no more than 1¼” diameter is used, 100% standard proctor density compaction can be obtained upon Feather Dumping and hand leveling. However, Class II and Class III soils should be Feather Dumped in layers so 95% compaction can be assured. Many knowledgeable pipe installers economized both labor cost and imported soil envelope cost at Class III clay soil sites by importing a Class II sand soil to mix 50/50 with the site native Class III clay. The Class III clay will generally provide enough moisture when mixed with the Class II sand to obtain a quick maximum compaction job with minimum effort.

cost component in any buried

pipe system. Easy handling

allows up to twice as much

CPP pipe installed per day compared to pipes made from

heavier raw materials.

To protect CPP pipes from H-25/H-30 construction loads prior to paving, a Mounding Ramp of 3 feet of compacted soil over the pipe should be utilized. The Mounding Ramp should extend to each side of the pipe for a distance of 1½ times the diameter of the pipe. This precaution should be taken at all construction crossover sites. Both asphalt and concrete greatly reduce the deflection potential on shallow buried CPP pipes to virtually zero deflection. Because paving does make it possible to use corrugated HDPE pipes at shallow or deep depths, CPP corrosion resistant pipes fill a multitude of cost saving needs on large paving jobs like shopping mall parking lots and airport runway stormwater control systems.

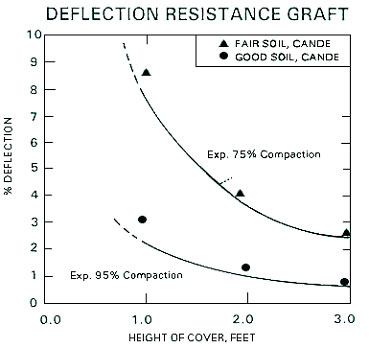

The following table gives the Minimum soil cover requirements for 12″ to 36″ diameter pipe as a function of H-Truck live loading. The cover depths shown have been tabulated for two soil conditions: (1) Fair, which represents a Class III soil compacted to 85% proctor density; and (2) Good, which represents a Class III soil compacted to 95%. The accompanying CANDE graft shows pipe deflection decreasing as compaction or depth increase.